W-Type Crystallization Tank With Jacket

Product Description

Technical Features

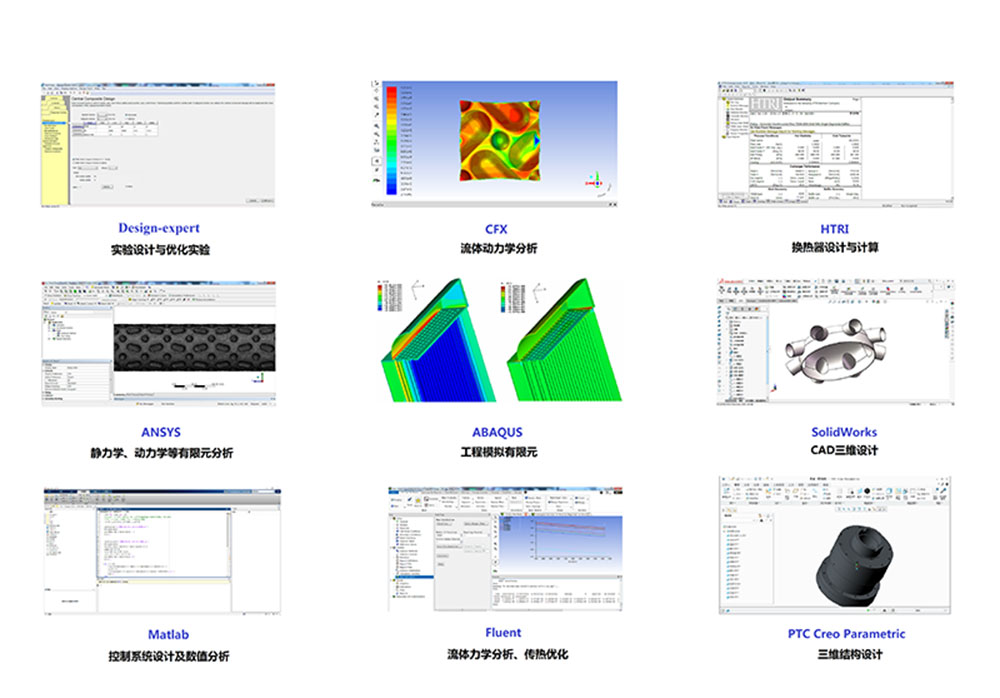

1. Customized design to meet various customers’demands

2. Drive device has compact structure, steady running, high efficiency, low noise

3. Reliable mechanical seal, low failure rate

4. Small gap between helical band and cylinder body, uniform agitation, no blocking

5. Advanced cycle water cooling system with good cooling effect, high crystallization effect

6. Stainless steel inner cylinder body, corrosion resisting, long service life.

W-Shape Crystallizer

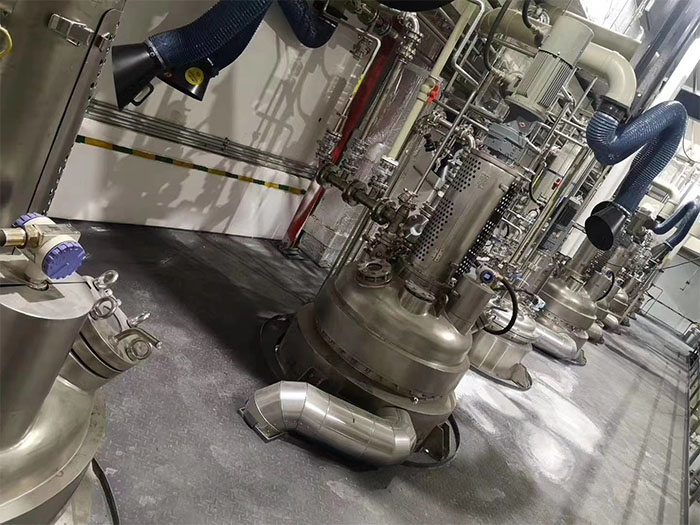

The crystallization tank is used for mixing and blending materials, cooling and freezing, and finished products crystallizing in pharmaceutical industry. The crystallizing tank is also widely used in dairy, food, chemical, beverage and Other industries. It can be made from SS304, SS316L, titanium, Hastelloy, PTFE lined or other material. The inside wall is treated with electrolytic Mirror polishing or mechanical polishing while the outside wall uses SS304 full-welding structure to preserve heat, and the outside surface is treated with mirror polishing or matte polishing.

| Specification (L) | Diameter (mm) | High (mm) | Pressure in the tank (MPa) | Pressure in the jacket (MPa) | Motor power (kw) | Rotation speed of blending |

| 100 | 400 | 2000 | 0.2 | 0.3 | 0.55 | 50-120 |

| 200 | 500 | 2330 | 0.2 | 0.3 | 0.75 | 50-120 |

| 500 | 700 | 2650 | 0.2 | 0.3 | 1.1 | 50-120 |

| ... | ... | ... | ... | ... | ... | ... |

| 20000 | 2300 | 2900 | 0.2 | | 30 | 50-120 |

1. Multifunctional “Three in One” (filtering, washing and drying)

4. Rake Vacuum Dryer /Paddle Dryer

5. Plate-fin Heat Exchanger

➤Our advantage

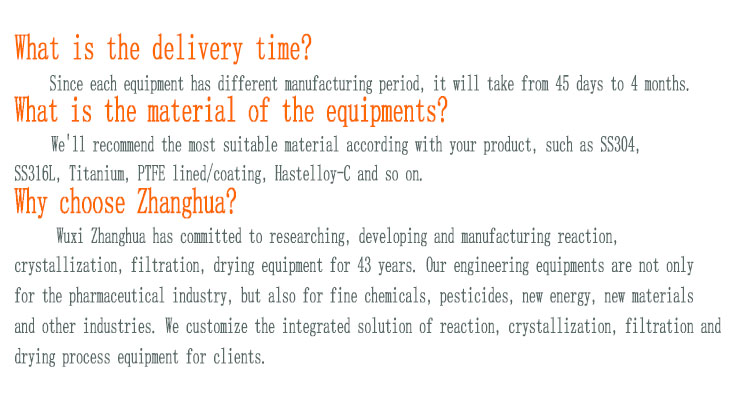

1. Special Equipment: Pressure Equipment, Equipment made of anti-corrosion materials, Sterile Equipment

Equipment made of anti-corrosion materials includes: anti-corrosion lining plastic/ PTFE/ enamel,

2.Customized Design: Double-Cone in 20L-20m³

Rake Dryer (with mechanical seal) in 16 m³

DN300-DN600 “Three in One”

3.Design/Calculation Software

➤scope of business

1. On-site Inspection

2. Technical Innovation Plan for Equipment Technical Improvement Plan for Equipment’s Structure Optimization Fast and Effective Solution to Equipment Malfunctions Highly Efficient and Precise On-site Construction Service Commitment to a Deadline in Customization A Full Range of long-term on-site technical maintenance service

3. Maintenance

4. Technical Solutions

5.On-site Testing and Training

6. Spare Parts

Product Categories : Crystallizer > W Shape Crystallizer